Production Process

Production process

01

Editing/design

Transmitted by network after editing/input/output of received data and samples in AUTO CAD/Illustrator

02

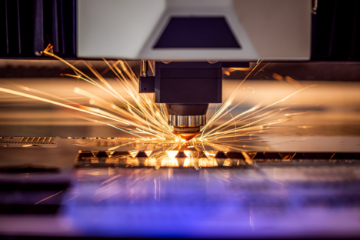

Laser cutting

Data received by ultra-precision laser Cutting of plywood, plastic, acrylic, etc.

03

Blade bending, cutting, laser welding

Automatically bent and cut by an automatic bending machine based on received data (laser welding if necessary)

04

Assembly

Automatic bending and cutting blades for laser-cut plywood are assembled by skilled engineers

05

Post production and inspection

Attaching sponges, subsidiary materials etc. to meet the user’s needs and quality inspection

Equipment

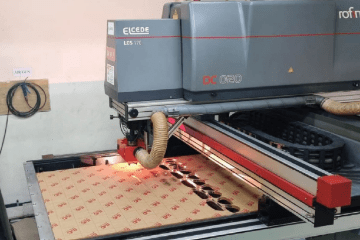

Ultra-precision laser

ELCEDE LCS 170The German-made ELCEDE LCS 170 ultra-precision laser is excellent ultra-precision laser equipment capable of producing very high-quality products.

- Flatbed Laser with 1.5Kw

- Rofin Sinar Laser source Slab 2 DC015 well maintained

- Working area : 1700 * 1500 mm

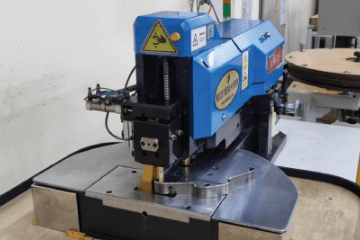

Thomson blade bending machine

MBS 450 / 710, AD240 and moreBusan Laser Die Cut has a total of four specialist bending machines, including one dedicated to 0.45 Thomson knives, one for 0.71 Thomson knives and a bending machine exclusively for 0.45 searing knives. Busan Laser Die Cut strives to develop products suitable for customer needs through continuous investment in facilities and R&D, maintaining excellent product quality and production speed by operating a development lab that integrates bending machines and various other equipment.

Laser welding machine

MBS 450 / 710, AD240 and moreIn order to produce high-quality products, we are committed to customer satisfaction by introducing a laser welding machine to further enhance the durability and precision of our products. The laser welding machine is a device that can manufacture Thomson molds that are more precise and durable than conventional welding machines. It has the advantage of increasing productivity by increasing the lifespan of the mold.

Other equipment

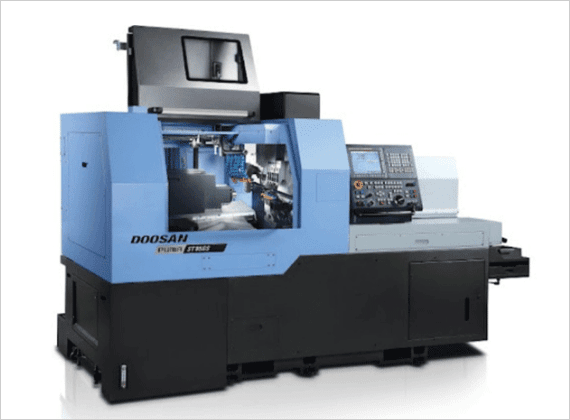

DOOSAN PUMA ST20GSBusan Laser Die Cut uses a DOOSAN PUMA ST20GS NC processing lathe, enabling very precise lathe processing and is establishing a system that can respond to customers’ needs.

20mm high precision, high-productivity Swiss turn

- Best-in-class speed and productivity

- Allows largest number of tools for its class

- Dedicated processing program operated for user convenience

- Realization of ultra-precision processing such as watches and medical supplies

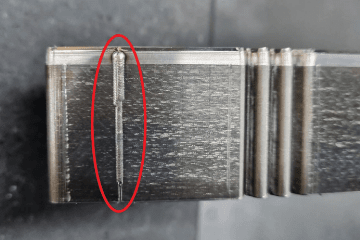

If bending is more difficult or more precision is required than can be provided by the Brother TC20A KNIFE, a CNC M/C is used for processing and manufacture.

When the height of a knife must be manufactured differently, the user’s order request can be met by making adjustments in units of microns.

When scrap from the Mitsubishi FA10SM has to be discharged or there is a risk of damage, this equipment is used to complete the processing with heat treatment according to the customer’s request.

Flatbed press

Thomson press machineBusan Laser Die Cut has a Thomson press machine and can manufacture press-processed products. From design to mold manufacturing and delivery of results, Busan Laser Die Cut provides a one-stop service.